Renovating KD4CSO's 1943 Vibroplex "Original" Bug

By Paul Bock,

K4MSG of Hamilton, Virginia

Click here for other articles by Paul posted to the LARG Internet Site

A little over a year ago, Arthur Laurent, KD4CSO, brought over several Vibroplex bugs that he had purchased as collectibles. All were in very nice shape except for a somewhat ratty-looking Original Standard from the early 1940s. The serial number (123xxx) showed it to be a 1943 model. Since I can't stand a dirty Vibroplex and Art was unwilling to attempt tear-down I offered to clean it, and after a long delay finally got to it.

As shown in the first three photos above this bug was pretty dirty and it was obvious that a couple of the top parts had significant plating wear even though most of the other parts looked OK. There were no speed weights but all of the remaining parts were present and appeared original except for a missing hold-down screw for the thumbpiece. The thumbpiece itself was in excellent condition (they are sometimes cracked or broken on older bugs). I did notice something a little unusual in that this bug had a solid brass nameplate whereas other 1943 thru 1945 Vibroplex bugs I've seen had brass-plated steel nameplates, brass having been a strategic war material during that era. Perhaps this bug was one of the very last ones made with the solid brass plate before the switchover (brass plates were reintroduced after World War II).

The photo below shows the bug parts spread out after disassembly but before cleaning.

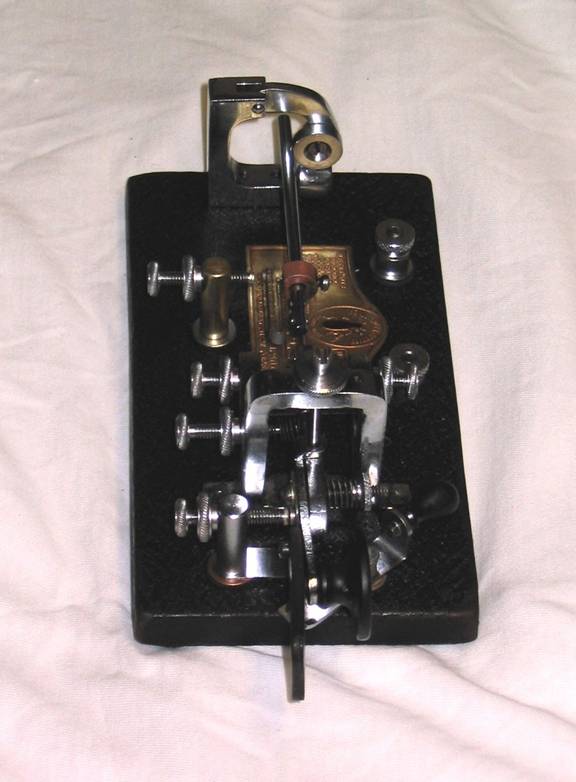

The last three photos show the bug after clean-up and reassembly. The chrome parts cleaned up exceptionally well; however, the dot contact post was brass and devoid of any plating at all while the moveable dot contact had the plating worn off down to the copper under-plating. They cleaned up well but of course will tarnish again rather quickly.

Another anomaly was that the dot contact screw had no contact installed, it was just rounded off as if with a file. However, the lever-arm adjusting screws on a Vibroplex have tiny holes in the ends so

that the same screws can be used as contact post screws by inserting a contact in the end, so I swapped out the rounded-off screw for one with a hole in it and inserted a contact. The contact I used is

the more modern large one (but was the same as the contacts on the dash mechanism) while the movable dot contact is much smaller, leading me to believe that the movable dot contact assembly may be of much

earlier vintage and may have been nickel-plated, not chrome, before the plating wore off.

With a couple of speed weights installed I gave this bug a try and while it sends fine the minimum speed is very fast, over 20 WPM , which is higher than I would have expected. I measured the thickness of the flat mainspring and it was 0.018", whereas most bugs of this era that I've ever seen have had 0.015-0.016" thick mainsprings. However, the lever arm is definitely post- 1940 chrome-plated, looks "period," and does not have the trunion pin adjusting screw that appeared about 1945, so who knows?

(NOTE: For those who don't know, mainspring thickness is the single most important factor in the MINIMUM speed of any bug. Many older Vibroplex bugs used 0.013-0.015" spring thickness and this gives a "sweet" sending characteristic. My shack bug, a 1922 Junior, has a 0.014" thick mainspring and has a wonderful feel at any speed. The Champion model usually had a 0.012" thick mainspring and a minimum speed of 14-15 WPM, which helped it earn a reputation as a good "beginner's" bug.) |

All in all this is a nice Vibroplex Original from the 1940s and will look good on the shelf. For on-the-air use I prefer one that will slow down to around 18-20 WPM and this one definitely won't unless you use a bunch of extra weight, which tends to make the sending mushy. So, I would lean towards just having it as a "display" bug rather than an everyday in-the-shack tool. But as the saying goes, your mileage may vary.

NNNN